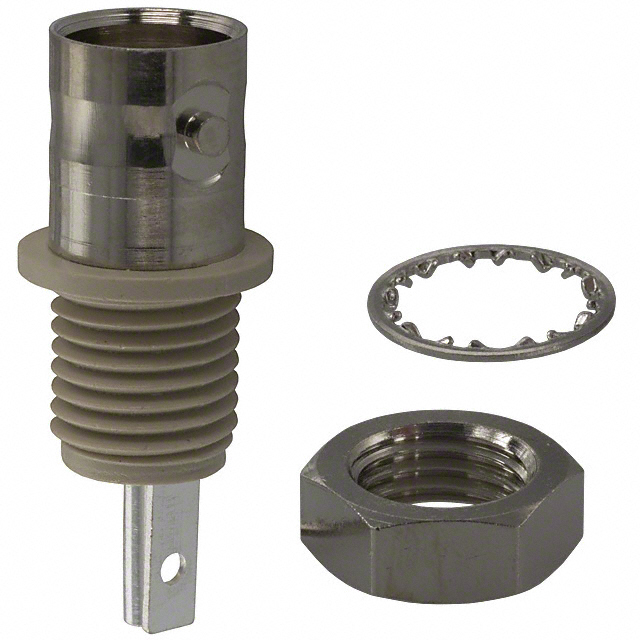

31-10

CONN BNC RCPT STR 50 OHM SOLDER

83-1T

CONN ADAPT PLUG-JACK UHF

11-140

CONN BARRIER STRP 11CIRC 0.375"

7-141

CONN BARRIER STRIP 7CIRC 0.438"

Y-141

CONN TERM BLK Y-SOLDER BARRIER

3-142

CONN BARRIER STRIP 3CIRC 0.563"

10-142

CONN BARRIER STRP 10CIRC 0.563"

8644

EJECTOR CARD LEVEL ACTION